|

Thousands of people are killed each year in rollover crashes. The best way to prevent these deaths is to keep vehicles from rolling over in the first place. When vehicles do roll, rollover curtain airbags help protect the people inside, and the use of safe seat belt designs is essential. However, even with these safety technologies, the roof must not intrude into the occupant survival space when it hits the ground during a rollover. "Roof crush," which is what happens if the pillars (the parts that hold up the roof, often called the A, B, and C pillars) and the window glass (which itself helps support the roof) aren't strong enough to hold up the roof when the car is rolling or upside down. Stronger roofs crush less, reducing the risk that occupants will be injured by contact with the roof itself. Stronger roofs also can prevent occupants, especially those who aren't using safety belts, from being ejected through windows, windshields or doors that have broken or opened because the roof has deformed.

During rollover crashes, all occupants, even those who are belted, can sustain head or neck injuries when their head hits the roof, particularly when the roof is in contact with the ground. On average, 6,500 people sustain serious injury annually due to roof contact where some amount of roof intrusion is present. Over half (3,450) of these injured people were belted.

The industry has studied the effects of rollovers and roof crush for more than forty years. The following two clips demonstrate how manufacturers succeeded in actually weakening safety standards. The first clip was shot in 1961 by Ford. At that time, engineers induced a rollover of a Comet station wagon. The narrator points out that the vehicle makes two complete revolutions and the roof never collapses.

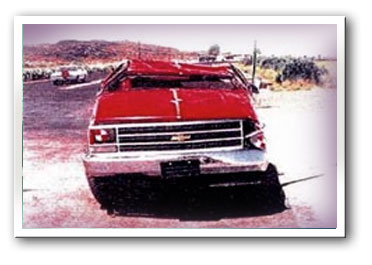

The next film clip involves an induced rollover of a 1988 Chevy pickup truck that met government standards at that time. During the first revolution, the Chevy truck’s windshield blows outward and the roof buckles. By the second revolution, the roof is completely crushed. Ironically, the truck would have failed GM’s own goals from the late 1960s, which provided that all vehicles withstand a 70 mph rollover.

Today the company avoids setting any such internal standards. Lee Brown says that simply meeting a minimum government threshold should not shield manufacturers from liability. “The manufacturers know that the government standards were inadequate. Many times they lobbied to make sure it wasn’t raised because of cost reasons. They knew that they had safer designs that could easily have been implemented—cheap and effective—but did nothing.” Brown adds, “The roofs could have been easily, easily made stronger for less than ten dollars a car. Same design, greater steel. Ten dollars a car and the odds of survival increased tremendously.” Indeed, after years of requests from consumer advocates, in 2009, the NHTSA issued a substantially stronger standard requiring the roof withstand three times the curb weight of the vehicle and requiring a two-sided test.

For more information: Contact Us

|